Personal tools

Mitaka Co., Ltd. at COMPAMED 2018

Mitaka is one of the leading companies in designing and developing tiny, sophisticated components for medical devices, semiconductor/substrate inspection equipment and electronic apparatus. Their core competence lies in the production of finest parts from micro (10-6) to femto (10-15) level, which is supported by nearly 30 years of experience in cutting, tip polishing, and bending. They have been certified to ISO 9001:2015 for the quality management.

Mitaka has contributed to the development of minimally invasive surgery by producing components mainly for endoscopes and endovascular treatment. They have outstanding techniques for producing straight stainless wires and long coiled sheaths, whose samples you can take a look at on their booth in COMPAMED 2018! The rest of their portfolio covers precious metal coils as well as stylets and mandrels, and these are in most cases designed as components and accessories for endoscopic treatment and inspection devices. Their micro coil springs are also suitable to use as embolic coils for brain and hepatic arteries.

Below are the details on their major 4 products:

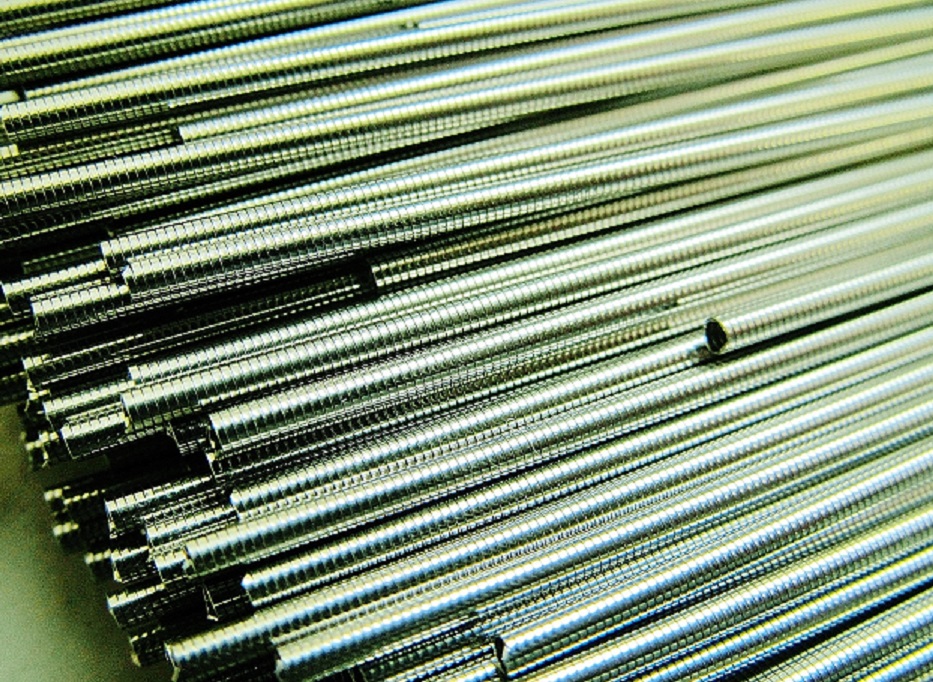

1. Metal straight wire – Straightness and very good performance on torque transmission Mitaka has been concentrating on an accuracy improvement in metal wire production for more than two decades. Subsequently, the company optimized their wires for guidewires to obtain a 1:1 torque transmission, which allows precise handling during procedures. Thanks to this characteristic, their wires are perfectly suited for application in angiography, PCI/PTCA, peripheral vessels, digestive organs, endoscopy etc.

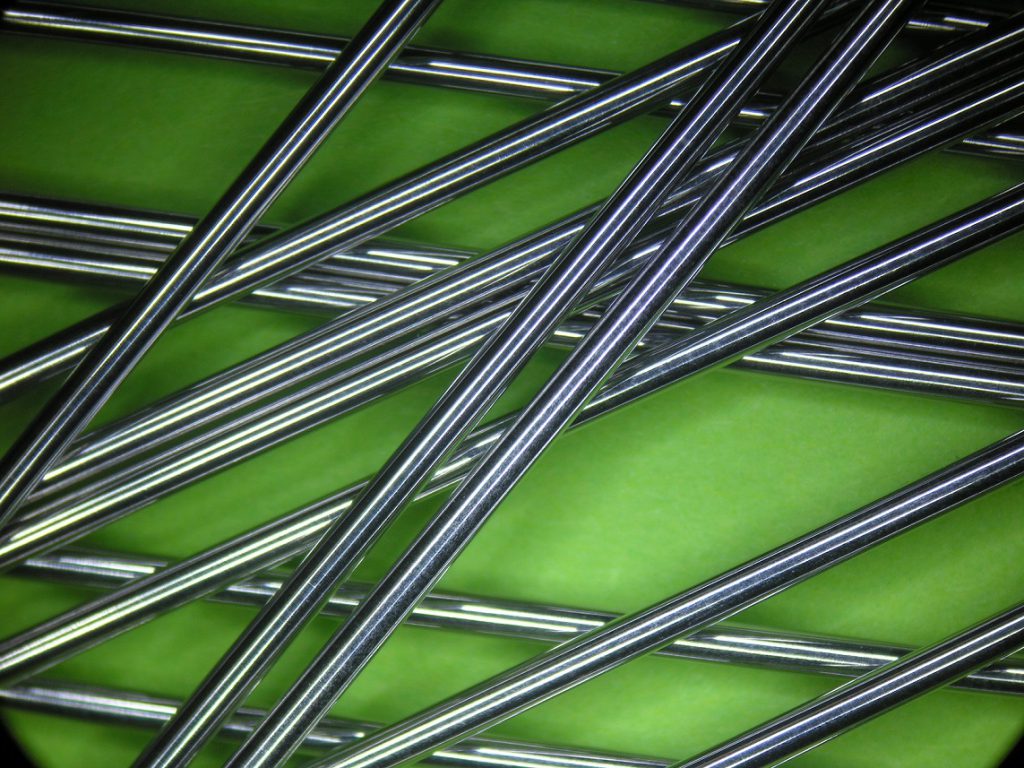

2. Long-coiled sheath – Smoothness and great responsiveness Their long coils are suited to catheters and endoscopic treatment tools, for they play a vital role in preventing kinks in resin tubes. The coils consist of flat wire so that the passing of cables is facilitated in comparison to round wires, and a higher flexibility than with metal pipes is achieved.

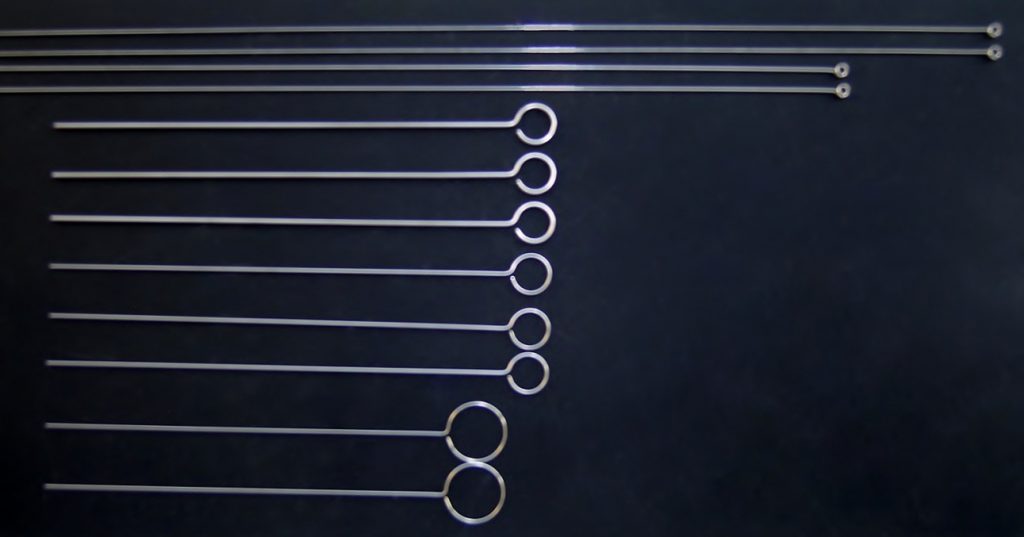

3. Micro coils – High accuracy of dimension Many years of experience in the production of precision coils enables them to cover large-scale orders of microscopic coils, made of precious metals and perfectly applicable to catheter and guidewire applications.

– Materials: Pt, Pt/W, Au

– Wire diameter: >0.04 mm

– External diameter: >0.20 mm

– Total length: up to 200 mm

Available options are as follows:

– Making a circle on one side

– Use of SUS materials (Stainless 304 etc.)

– Total lengths of up to 1,700 mm with wire diameters >0.2 mm

– Tapering and coatings

At COMPAMED 2018, Mitaka will be showcasing their capabilities in microscopic processing with the examples of highest quality straight wires for guidewires and long SUS square wire coils. Visit them in Hall 8b, stand H21 at the COMPAMED booth of the Saitama City Foundation for Business Creation!

Would you like to learn more about this company’s technology or arrange a meeting with them at COMPAMED 2018 in Düsseldorf? You are welcome to contact us anytime.

MITAKA Co., Ltd.

1765-1 Menuma, Kumagaya-shi, Saitama 360-0201, Japan

Tel: +81-48-588-5552 Fax: +81-48-589-0040

Mail: info@t-mtk.co.jp

URL: http://www.t-mtk.co.jp/original10.html