Personal tools

Origin Electric Co. Ltd. at the Cluster Symposium 2016

|

Origin Electric Co. Ltd. |

|

Origin Electric Co. Ltd. is located in Saitama prefecture and specialized in welding machinery. Since 2005 their Mechatronic Division develops devices that improve functionality and productivity of custom products. Their core technologies are the following:

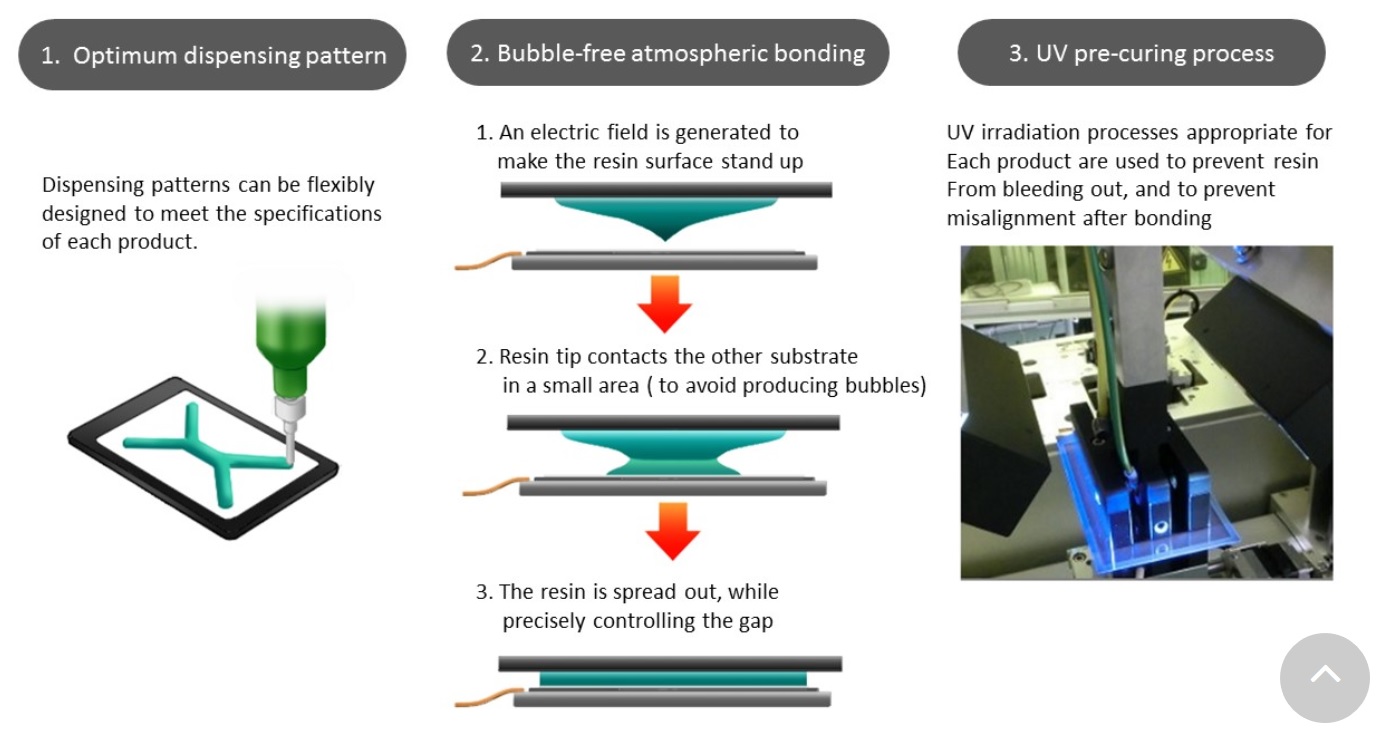

– precision dispensing and coating

– bonding of resin

– vacuum soldering

– flux-less soldering technologies

In Ingolstadt Origin Electric Co. Ltd. will present two of their cutting-edge technologies: its Mobile Display Bonder (MDB) and its vacuum reflow soldering technology.

Mobile Display Bonder

Origin’s Mobile Display Bonder (MDB) is an ideal solution for the production of various kinds of displays:

![]() Origin’s Mobile Display Bonder

Origin’s Mobile Display Bonder

Vacuum Reflow Soldering System using formic acid

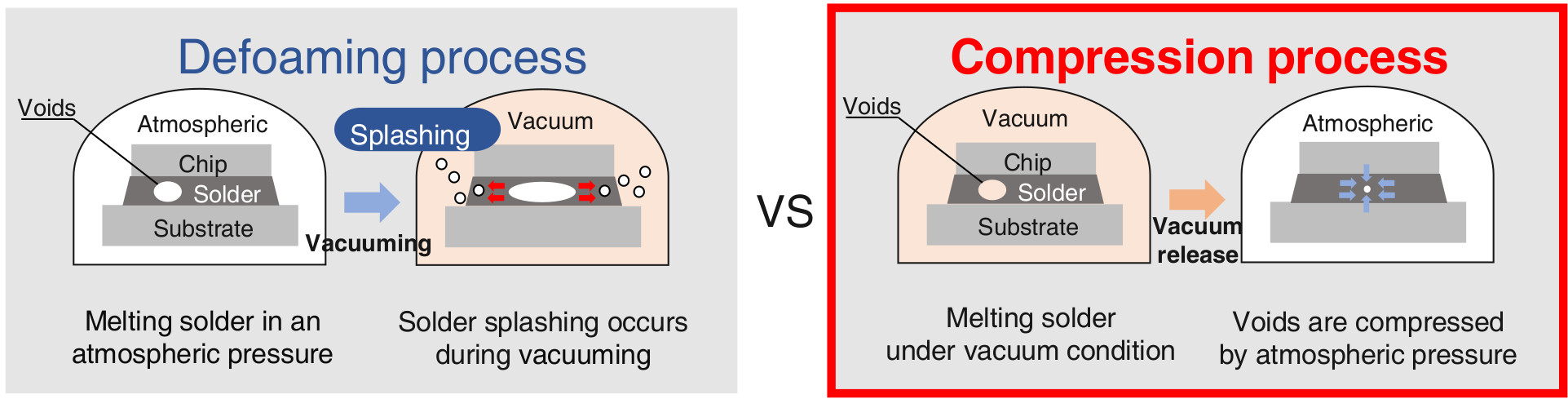

Origin’s Vacuum Reflow Soldering System combines the possibilities of formic acid reduction with a compression process for a fluxless formic reflow soldering method. This not only renders the use of solder flux and the removal of flux residues unnecessary, but also prevents voids and flux spillage at the same time.

In comparison to conventional approaches to soldering in reductive atmospheres that utilize hydrogen, using formic acid for reduction allows lower processing temperatures while improving the wettability.

Additionally, Origin’s special compression process effectively prevents the forming of voids and flux spillage during the vacuum soldering better than conventional methods.

Conventional approaches often utilize a defoaming process: Solder is melted under atmospheric pressure and then a vacuum is created which creates voids or might lead to spillage of flux or solder. But Origin’s approach is different: After solder is melted under a vacuum a compression process will take place under atmospheric pressure which compresses any voids inside the solder.

|

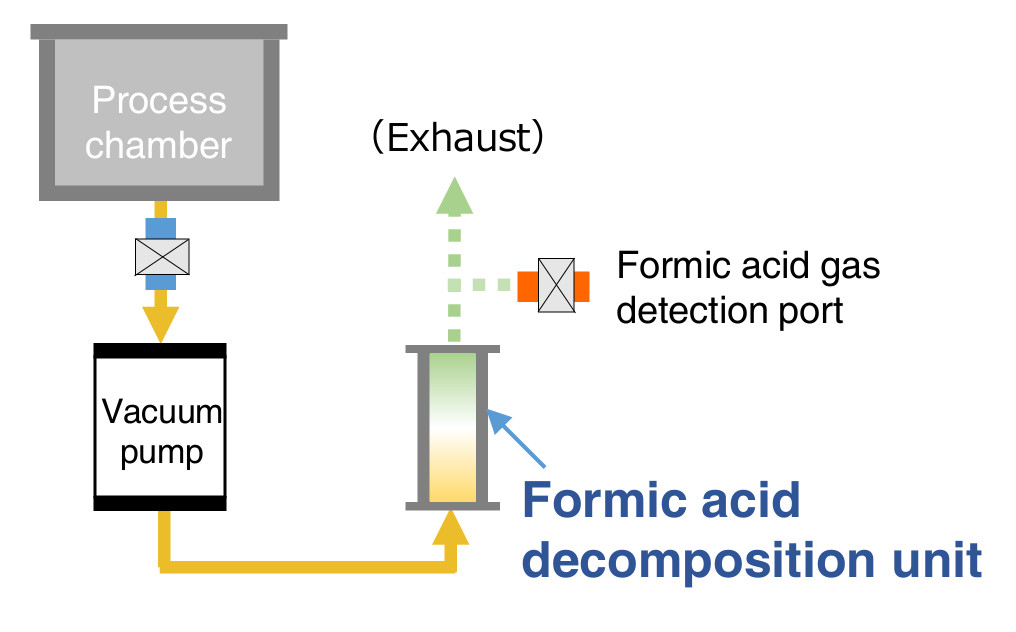

The system depends only on a minimum usage of formic acid which after the process is completely eliminated.

|

|

![]() Overview on Origin’s Vacuum Reflow-Soldering System

Overview on Origin’s Vacuum Reflow-Soldering System![]() Catalog of Origin’s Vacuum Soldering Systems

Catalog of Origin’s Vacuum Soldering Systems

Detailed description of Origins technologies and company profile:

http://www.origin.co.jp/eng/business/mechatronics/

Visit Origin Electric Co. Ltd. at the Cluster Symposium (20.-21. September 2016) in Ingolstadt!

You want to make an appointment with Origin Electric Co. Ltd.?

Then please send a mail to: mail@ichconsult.de

Origin Electric Co. Ltd.

Meiji Yasuda Seimei Saitama-Shintoshin Bldg. 13F

11-2 Shintoshin, Chuo-ku,

Saitama-shi, Saitama-ken,

330-6013, Japan

www.origin.co.jp/eng